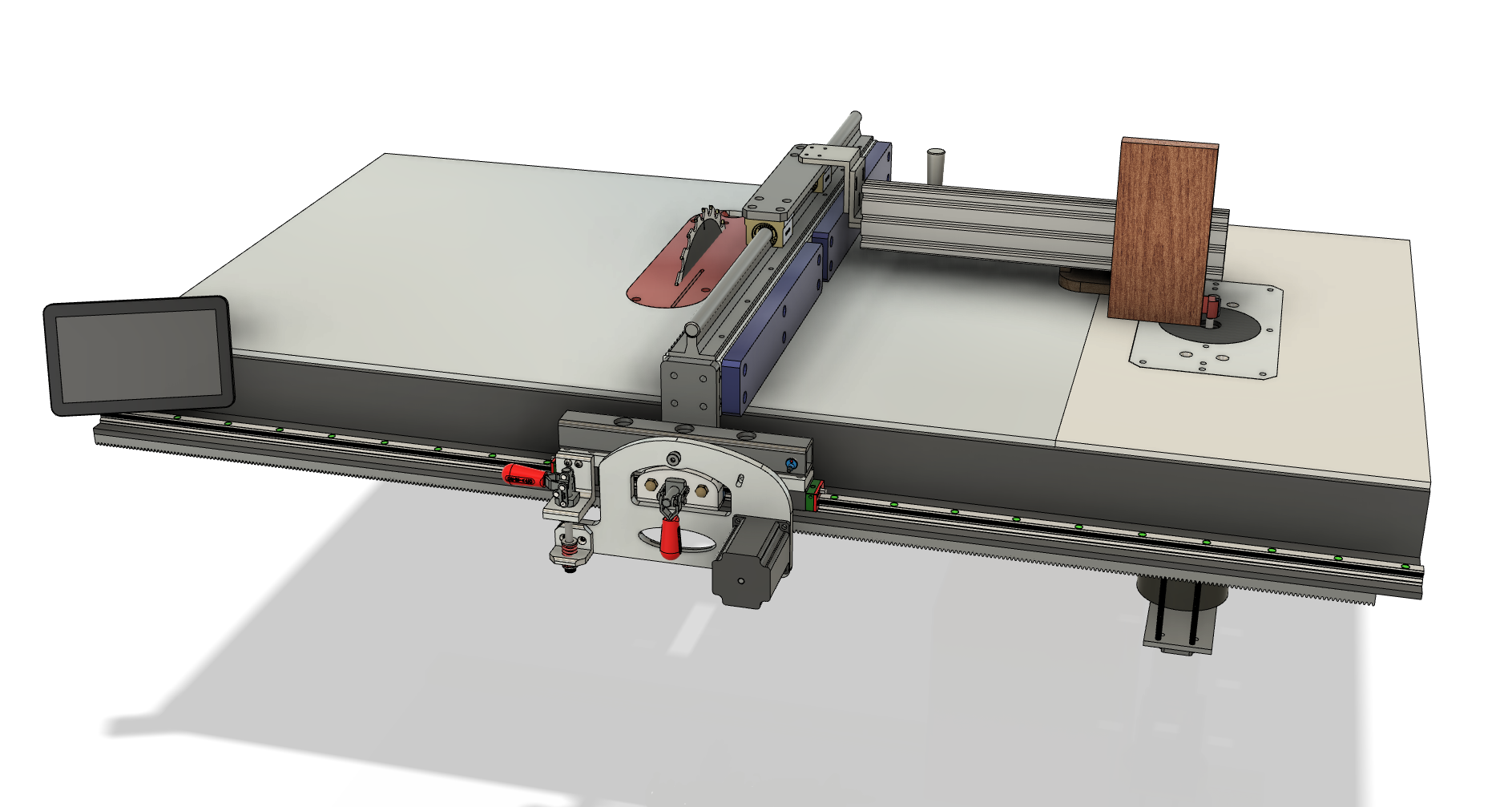

Automatic Table Saw Fence, Router Lift and Joinery Maker

By Richard Want

This is a system that calculates and automates a few different woodworking processes on-the-fly with very high precision.

Type: Commercial, Artistic

What inspired you or what is the idea that got you started?

I’m a hobbyist woodworker. I’ve been slowly building up my tool arsenal after losing everything in Hurricane Sandy. I like to design and/or make my own tools when I can (CNC router, 13” wood jointer, etc.)

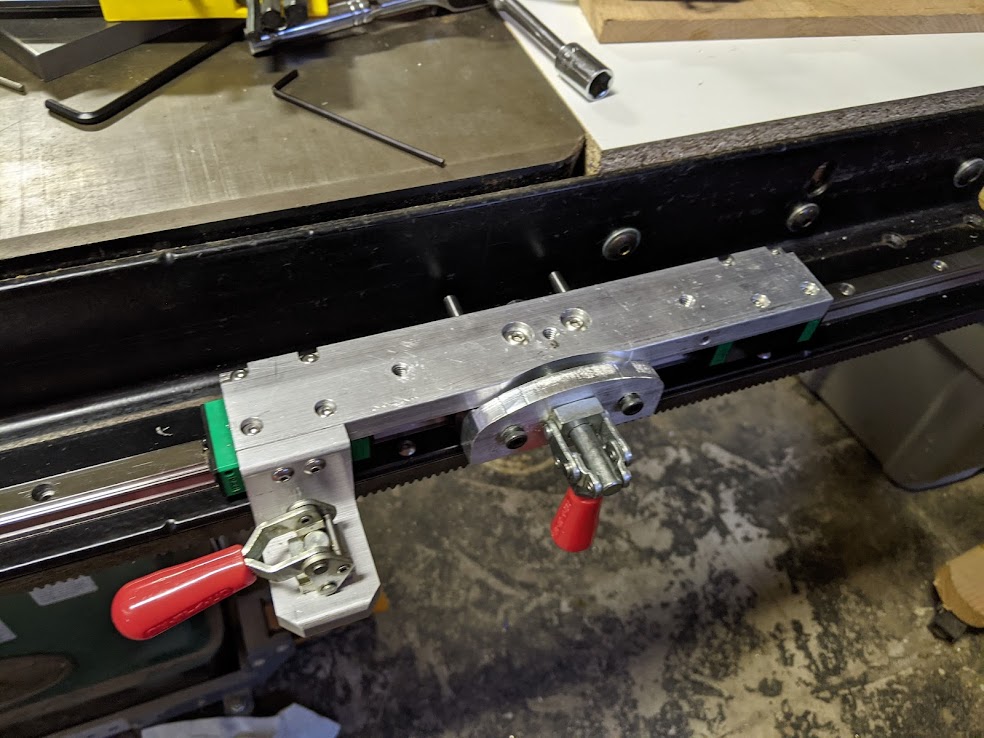

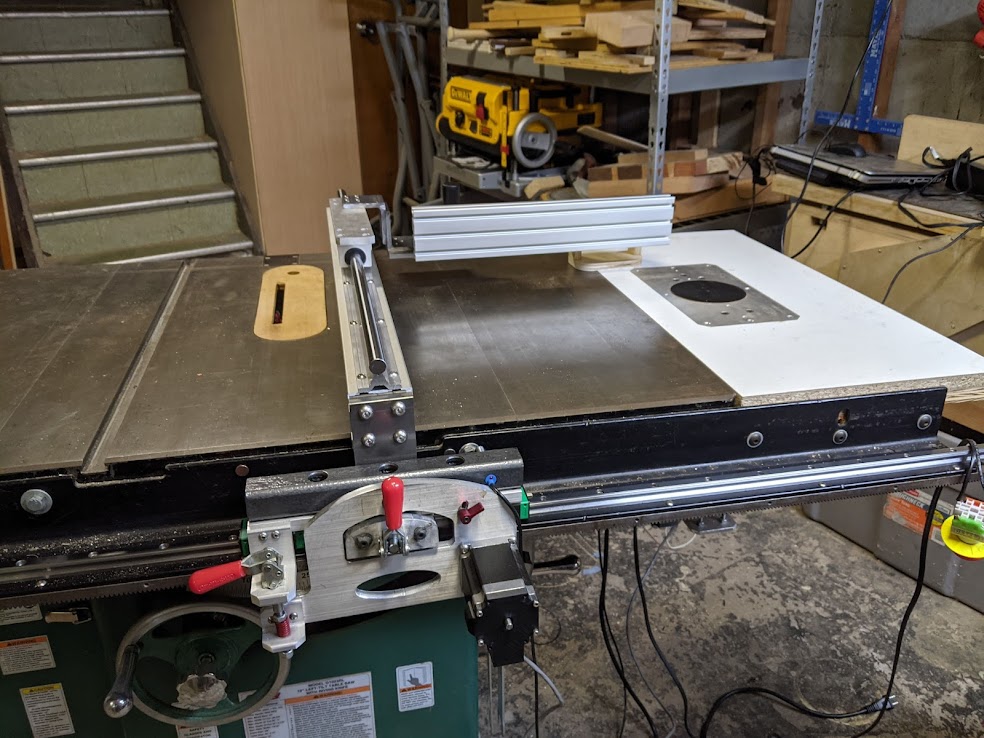

I bought a used table saw and built a router table extension for it. I wanted a fence system for both that could do customizable joinery (like dovetails and box joints). There aren’t any commercial systems available that incorporate these features in a digital package. There are some systems that use premade templates, but these are somewhat limited (and I thought too expensive to justify in my case)

By this time, I had been teaching myself to use CAD/CAM, had begun playing with a 3D printer, and had made my own CNC router. I had some leftover aluminum and bearings.

I had zero programming knowledge and I thought this would be a good project to learn.

What is your project about and how does it work?

My project is a digitally controlled table saw fence and router table lift that is capable of making customized joints and common woodworking processes with high precision.

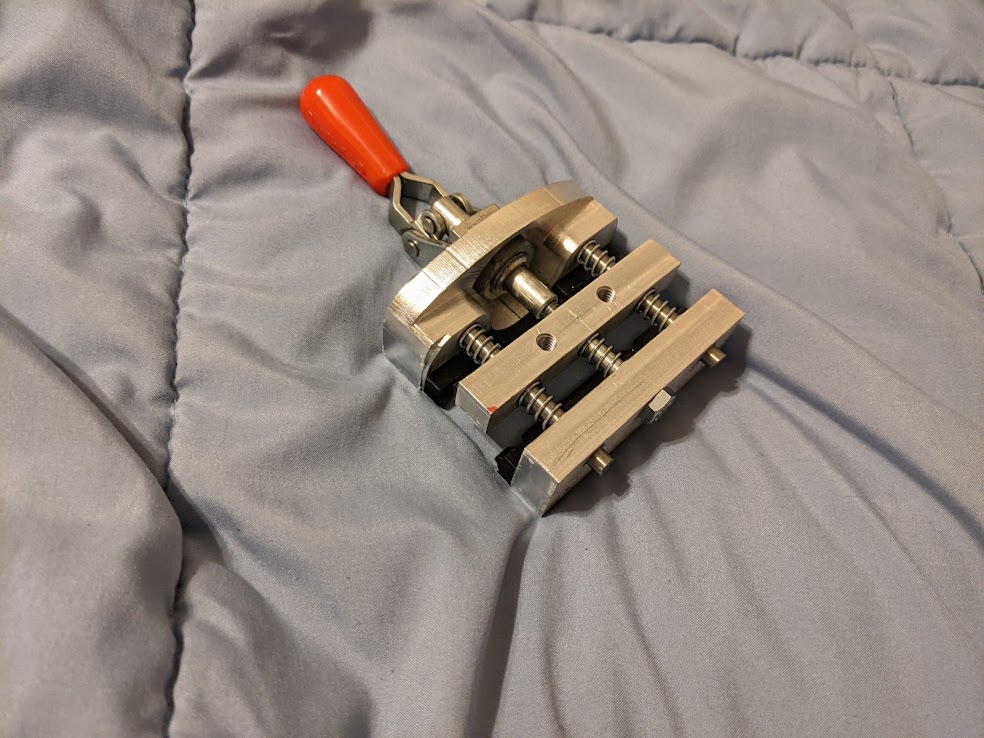

I wanted the ability to use my system in a traditional way, without needing to use any electronics, as well as to switch on the fly to using it in digital mode.

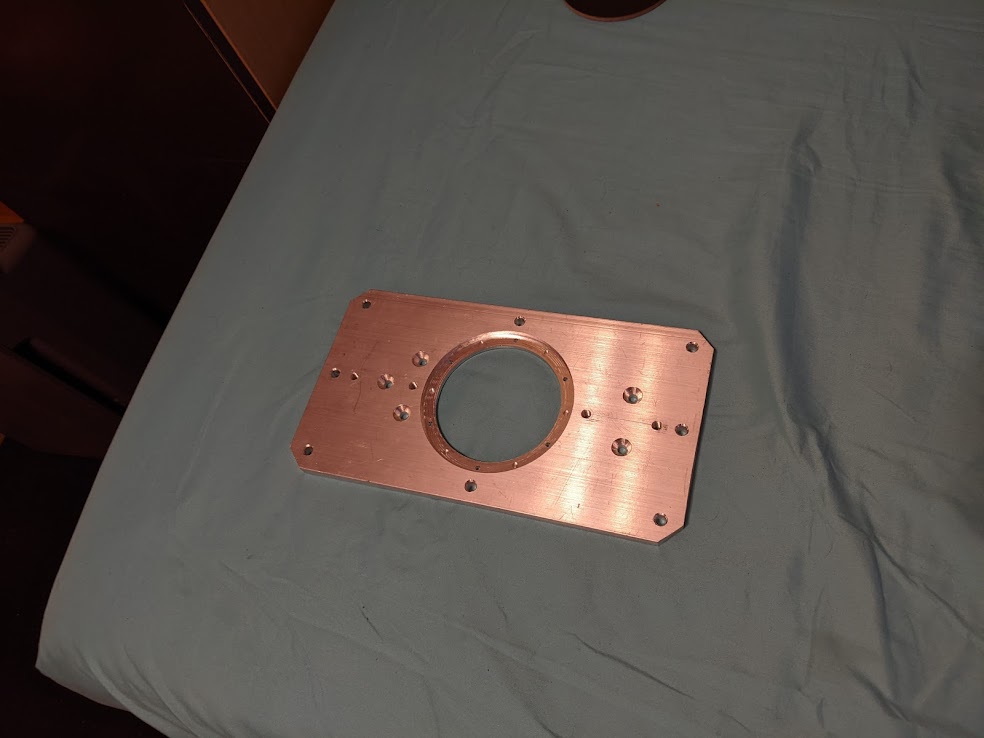

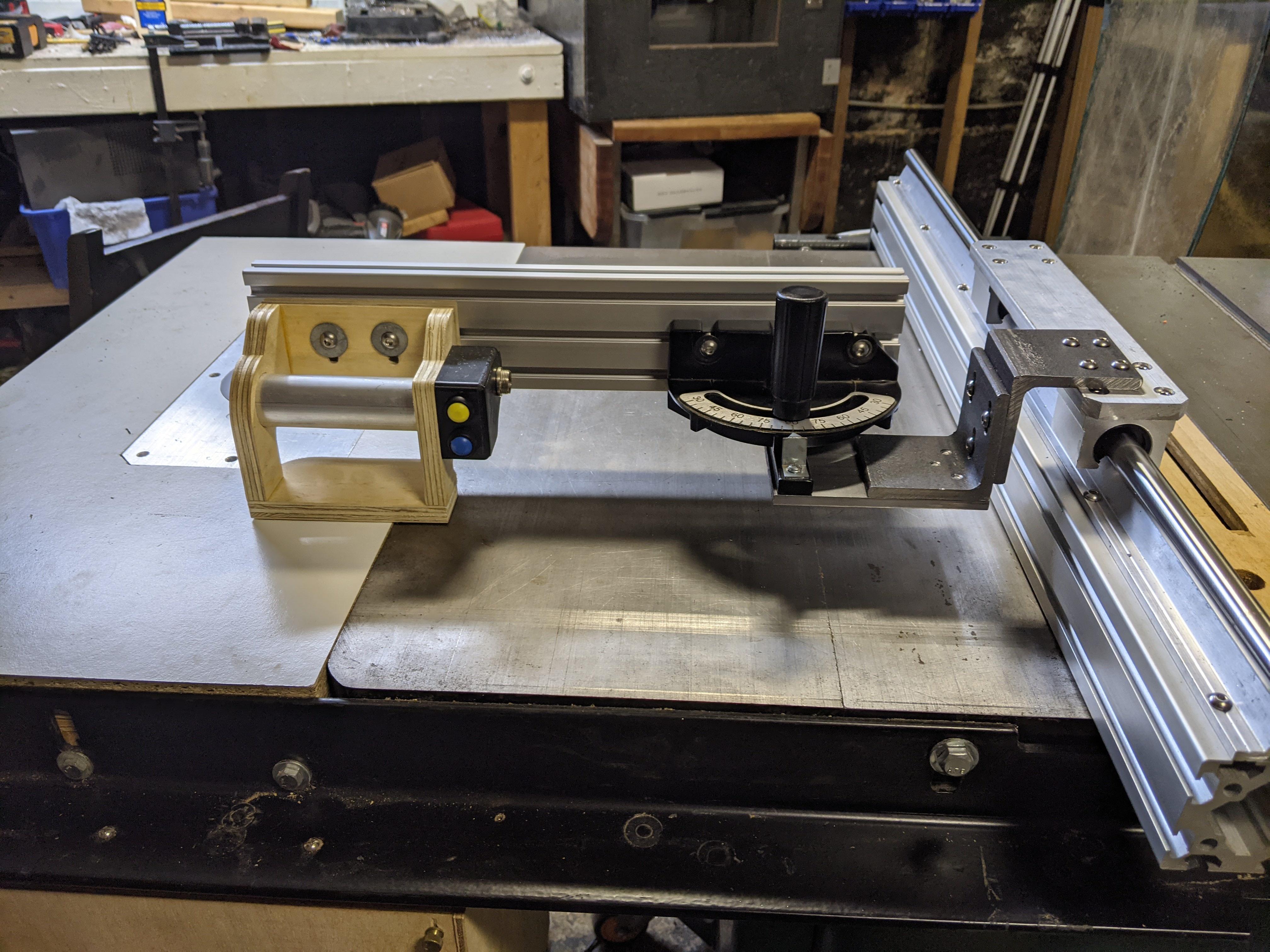

The hardware is the result after 5 iterations in CAD and is all custom-made by hand, CNC router, and a 3D printer. Both the fence and router lift make use of a stepper motor.

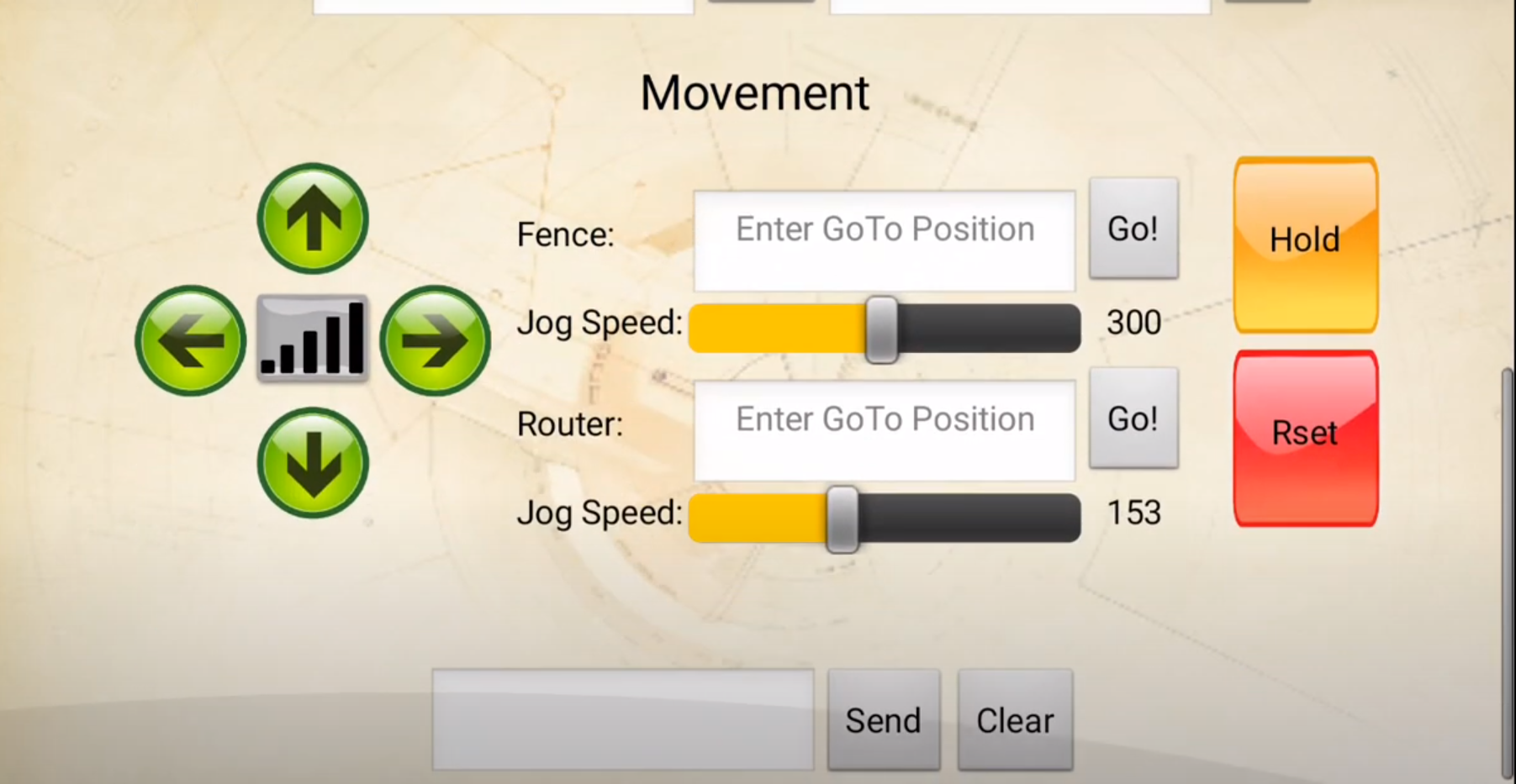

These motors are controlled by an Arduino that runs a motion controller. This is serially connected to an esp32. I use the esp32 to pass through Bluetooth data to/from an Android tablet as well as to monitor physical buttons that interact with the system. The fence references itself using a hall effect sensor and magnets, while the router lift uses a simple touch plate.

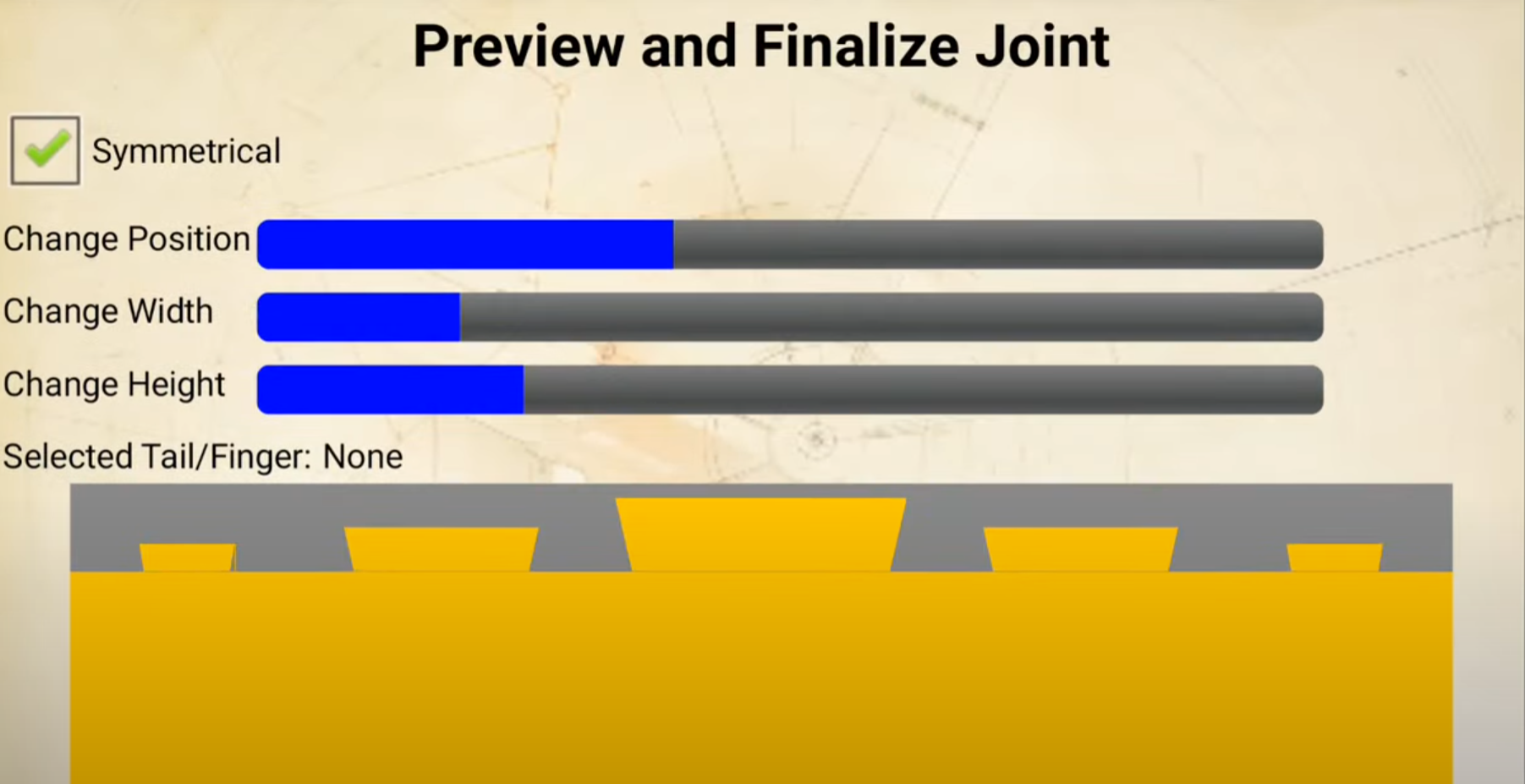

The tablet runs an app I made with many features like:

Offsets, tool libraries, joinery customization, etc

What did you learn by doing this project?

Aside from wanting to have and use this system, the primary reason I made it was to use the project as a vehicle to begin learning how to code. The android side started off as java in android studio. As it got more visually complicated, I wound up converting it to Kodular and made custom java extensions to get it to do what I wanted. I have since moved on to teaching myself python and have been having fun exploring AI. I’m looking forward to combining this with my medical background.

I also learned to practice patience. This project is/was a large undertaking for me and has taken quite a bit of time. My goal isn’t to finish it by a certain time, but to learn all I can and be happy with what I made before I move on to the next part. Rather than starting to build as soon as I had a design, I kept iterating in CAD until I thought my design was as good as I could make it given the tools and skill level I had.

What impact does your project have on others as well as yourself?

So far, this system has greatly simplified and increased the precision of my woodwork. It also makes it more fun. The hardware side of the project is fairly complex, and I don’t know that it can be replicated that easily. Once I have fully developed the system, I’m going to focus on simplifying the hardware design so that either others can build it at home or it can be produced as a commercial product. I’m not sure how much demand there is for something like this and I don’t yet know enough about different distribution licensing.

On a personal note, working on the project has had a profound impact on my confidence in taking on challenges even if I don’t initially know how I will meet them. I didn’t really know how I would complete this project before I started, but I gave myself the time to figure it out.