Cable Drive

By Richard Emmett

An aerial cable and electric vehicle is the most efficient way to move an object from point A to B. It requires minimum energy to set up and operate and is inherently safe and reliable. This Maker Project is a working “proof of concept”

Type: Social Impact

What inspired you or what is the idea that got you started?

I first got interested in Aerial Transportation when I took my children on a Zip Line adventure and was amazed to see how incredibly energy-efficient and safe they are; compared to driving or flying.

I realized that:

1/Automobile traffic is getting worse everywhere. The problem is the roads and intersections, and cities have no space for more.

2/ Modern cables can be very long, super strong, and cost less than roads, bridges, or tunnels.

3/ With Covid, shared public transportation is a health risk, and vehicles with fewer passengers are better for cables as they reduce sag.

4/ An affordable public transportation system must be fully automated.

I know no city will accept such a radical idea as Aerial Transportation without careful study. Even a research university will not investigate without some "proof of concept."

I thought a "Cable Drive" Maker Project that can safely deliver a small load up and down a cable with precise automated control would be an excellent first step.

What is your project about and how does it work?

This Maker Project aims to develop an electric Cable Drive that can safely deliver a small load up and down a cable, entirely automatically, with precise speed and distance control.

The cable is 1/4 in. 7 x 19 stainless steel; and is suspended between two existing fixed vertical supports for testing. Even this inexpensive cable can support over 1,000 lb.

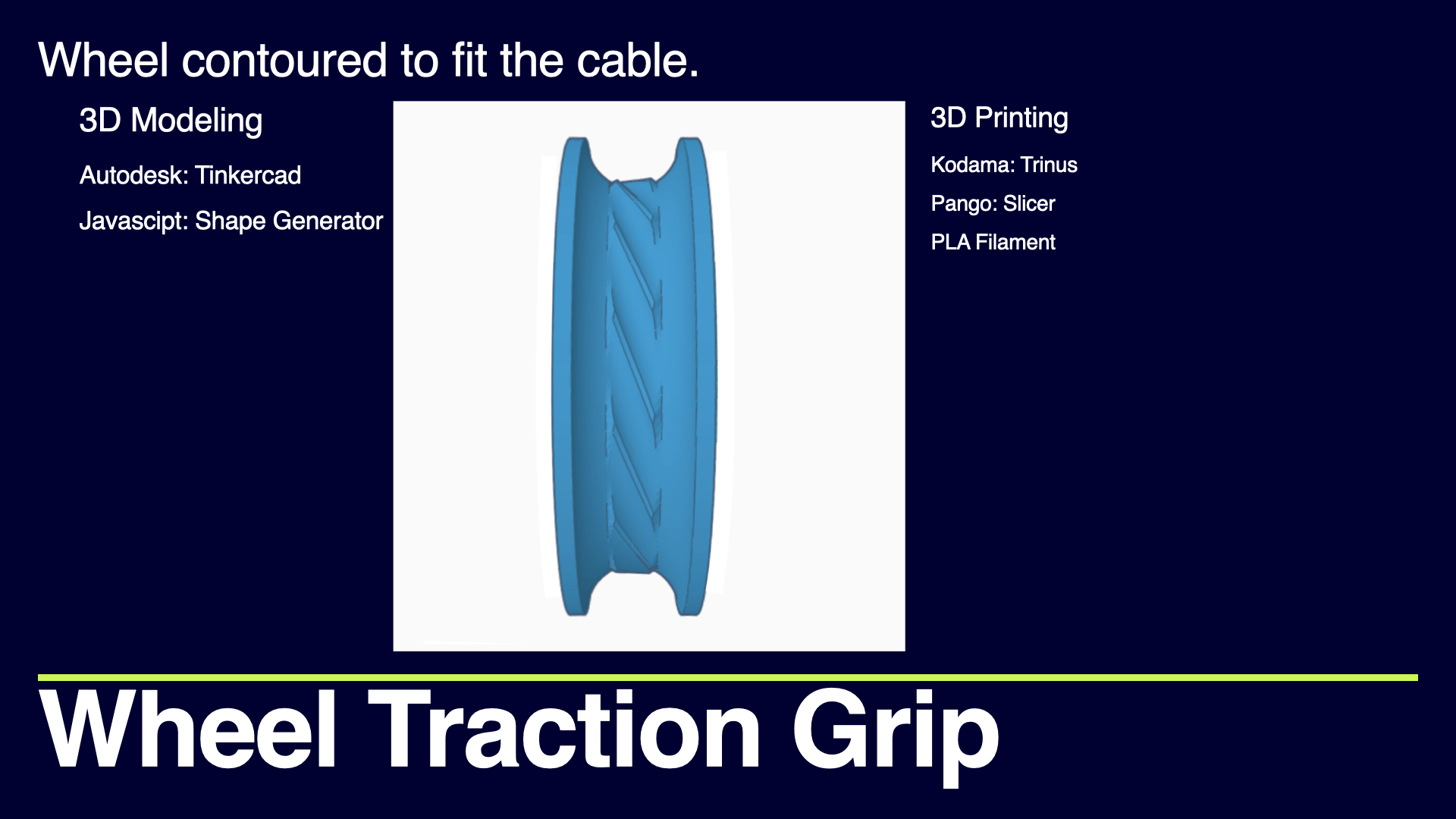

The wheels are contoured to fit the cable to provide traction. The wheels were 3D modeled using TinkerCad and a custom Shape Generator written in Javascript. Then 3D printed using a Trinus 3D printer and PLA filament.

Each wheel has an electric drive: A Nema 17 Short Body Bipolar Stepper Motor. An A4988 Motor Driver with Heat Sink, And a 12-volt battery box.

An Arduino UNO microcontroller board and custom test program written in C control the model. The program sets the direction of travel, then sends a stream of step commands to all motors.

The program completely controls the model, so it is entirely automated.

What did you learn by doing this project?

I consider this a small but successful Proof of Concept because:

1/ The wheels securely grip the cable.

2/ The three and half-pound model can reliably climb a twenty-degree slope.

3/ The motors provide precise control of speed and distance.

4/ The computer and software fully automate the model.

I was surprised by how easy it was. It worked the first time, even using a 0.2 mm print nozzle and poor woodwork. I suspect a more precise model would do even better.

Note: A cable drive is self-steering because the model follows the cable. It is safe as long as the cable path is separate from any potential hazards. And can be very energy efficient since the vehicle does not need metal armor, airbags, or complex suspension.

I hope other Makers and Engineers will jump in and help scale up to life-size. There are many exciting areas to investigate: Higher speed, Material wear, Electrical consumption, Cable switching, etc.

What impact does your project have on others as well as yourself?

I hope this project and the publicity of this competition will spark public debate on Aerial Transportation. And that in the future, cities will have public transportation that is fast, safe, clean, green affordable, and reliable. And the surface of our cities will be reserved for people, bicycles, trees, outdoor cafes, etc.

I hope other people seize this opportunity and make it happen; it becomes the next “big thing” in the business world; and makes city life better for everyone.

I can also imagine lots of other applications:

1/ Parts delivery in factories.

2/ Package deliveries in cities.

3/ Emergency bridges in disaster areas.

4/ Exciting new rides at amusement parks

5/ Flying ghosts at Halloween.

I am sure the Maker community will think up many more.