Remote-Controlled Robotic Leaf Blower

By Brian Wiggin

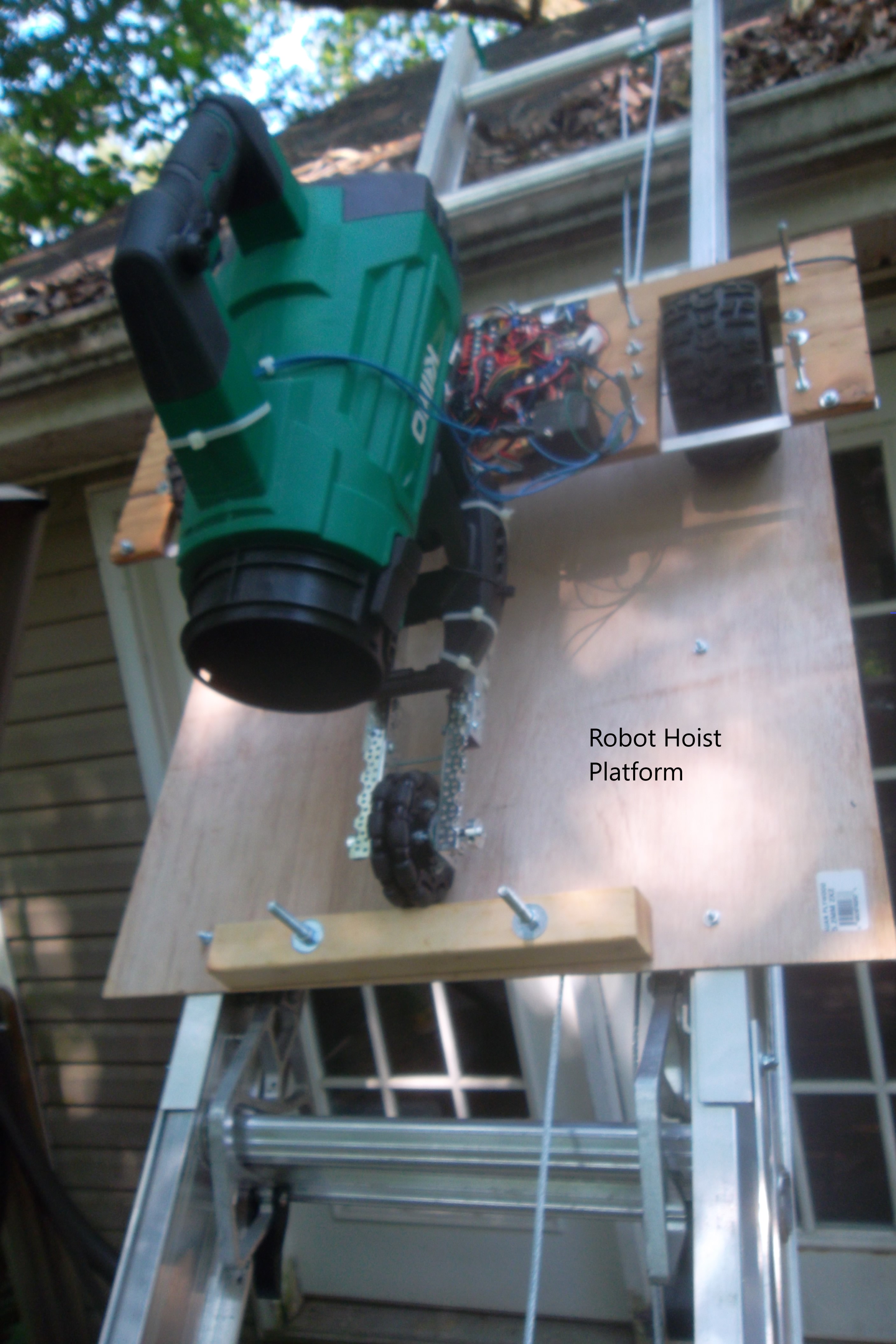

Remote controlled leaf blowing robot utilizing a custom roof hoisting mechanism

Type: Education

What inspired you or what is the idea that got you started?

Removing leaves from a roof high above the ground is a problem from a safety standpoint as well as being physically difficult for most homeowners living in a wooded area. Initially, the challenge was building a remote-controlled robot that could climb a steep roof with less than a 24-degree slope on slippery leaves while utilizing a commercially available leaf blower. Eventually, the challenge also became designing a means to hoist a 25-pound robot to the roof using tools readily available to the average homeowner. The hoist mechanism would need to be able to hoist the robot to the roof on a ladder with less than a 45-degree slope and allow the robot to proceed onto the roof without requiring the user to climb the ladder or get on the roof.

What is your project about and how does it work?

This project employs standard parts to build a remote-controlled robot designed to blow leaves off a roof. It includes a mechanism for hoisting and deploying the robot onto the roof.

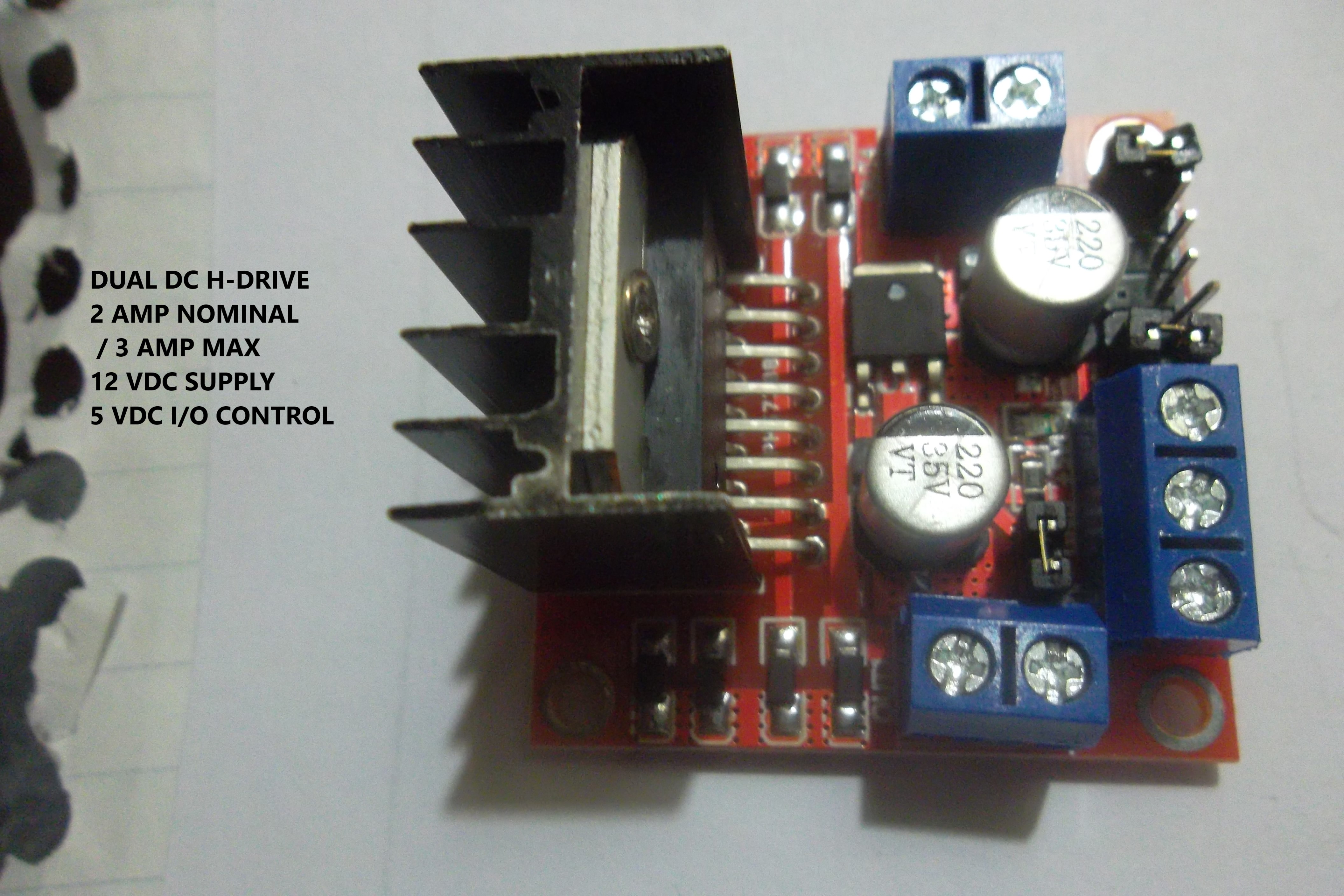

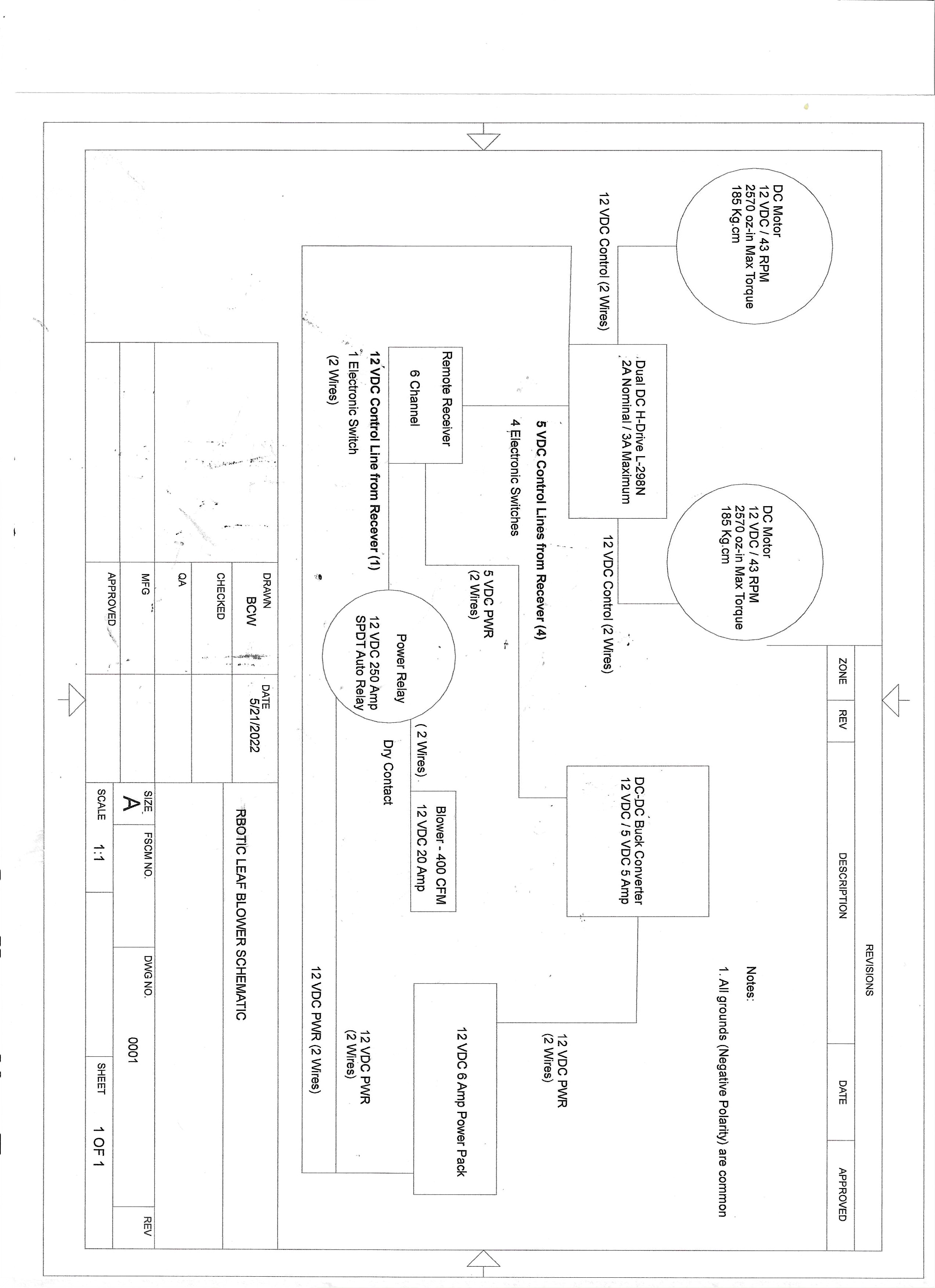

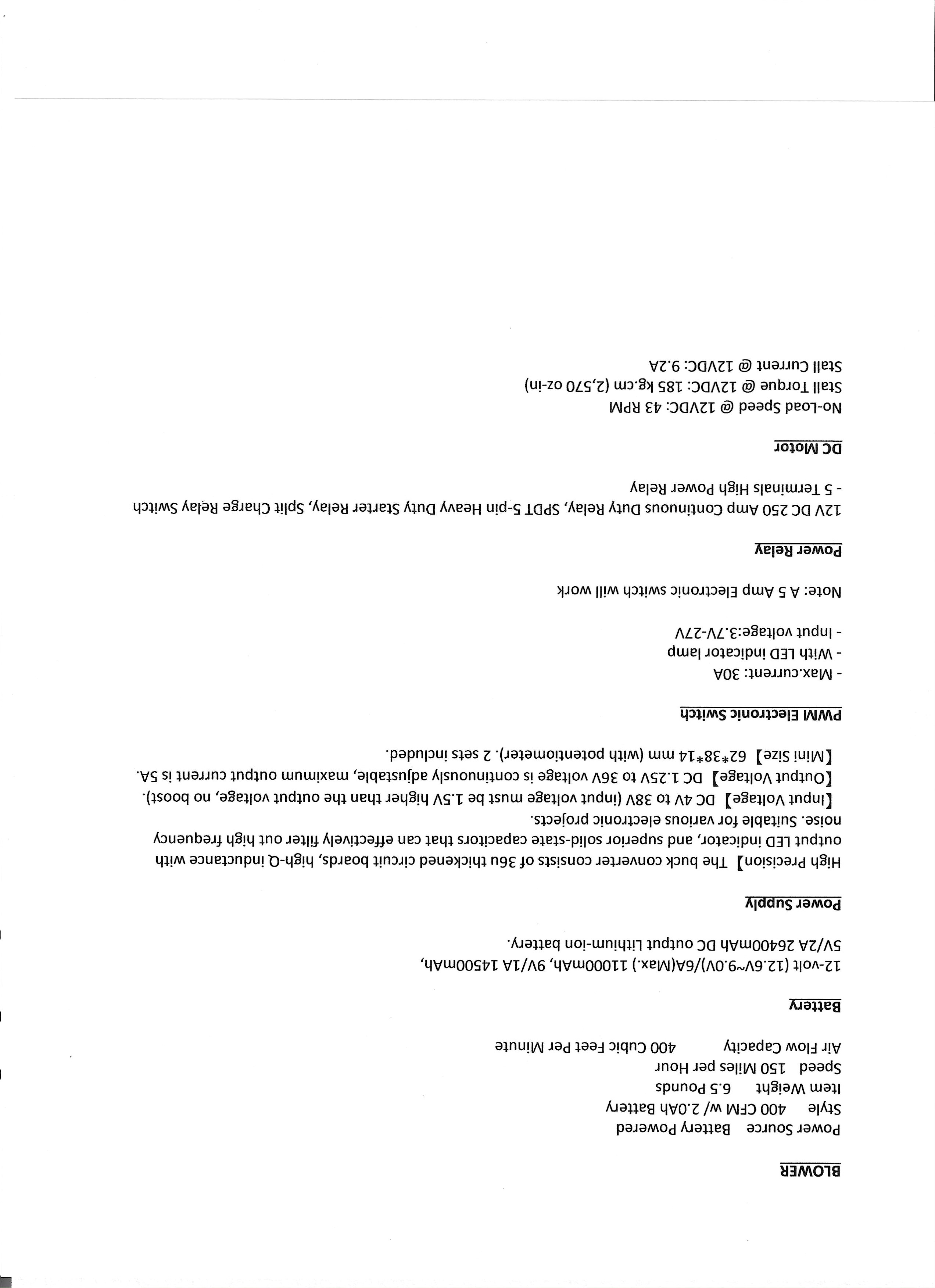

The robot utilizes a 6 Amp 12-volt rechargeable battery pack used to operate two 12-volt 43 RPM 2570 oz-in DC-Drive motors, a dual-motor H-Drive as well as a buck-converter 12vdc-5vdc-5 Amp power supply for operation of the onboard radio receiver.

The radio control system consists of a 6-channel servo transmitter and receiver. The receiver output operates 30 Amp PWM electronic switches for controlling the DC-Drives and the 250 Amp Power Relay for the leaf blower.

The robot utilizes two 6-inch rubber-tired wheels and one 4-inch Omni-directional front wheel. The 6-inch tires have treads designed for all-terrain mobility.

The robot hoisting mechanism utilizes a 600-pound trailer winch and one pulley along with aluminum sliding metal supports and a plywood platform to hold the robot.

What did you learn by doing this project?

Although the robot and hoist mechanism function as intended, various improvements will be made to assure reliable and better performance. I will add two more DC drives to obtain improved traction on dry leaves. These drives will be hooked-up in parallel with the two existing motors - making two right-side motors and two left-side motors. The hoist mechanism will receive better support to secure the robot while in lift mode - but its basic operation will remain the same. However, the hoist slide-hinge mechanism will be improved to prevent potential binding.

An onboard camera - ESP32 AI Thinker - will be added for real-time viewing and recording of the area where leaves are being removed. Ultrasonic sensors will be added to the front and back to provide auto-control functions to prevent getting too close to the edge of the roof.

More testing and adjustments will be necessary once the extra motors are added to avoid excess rolling when stopping on the roof.

What impact does your project have on others as well as yourself?

This project is a prototype and is not a commercial product. This project proposes a safe and effective method to remove leaves from a standard roof without climbing a ladder or getting on the roof.

The robot hoisting mechanism and assemblies including the ladder used in this project should not be used for climbing by humans - it was designed for robot hoisting to allow the robot to access the roof for leaf blowing.