The ASCAND – 3D Printable 3D Scanning @ Laser Precision for All of Us

By Gerrit Kolb

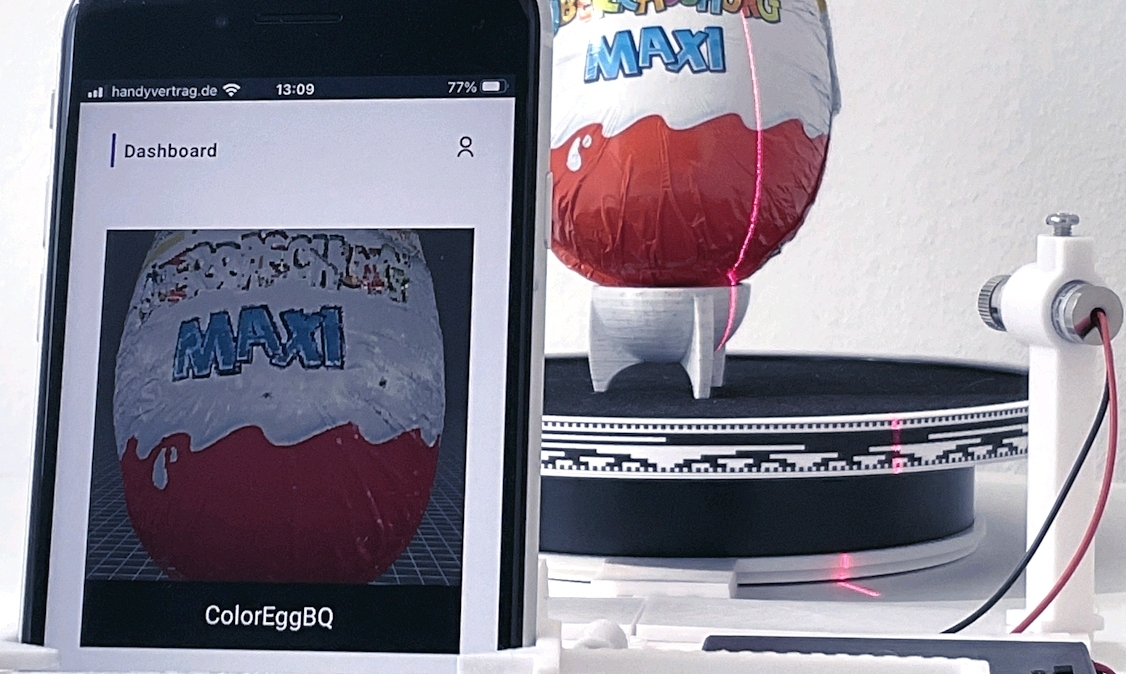

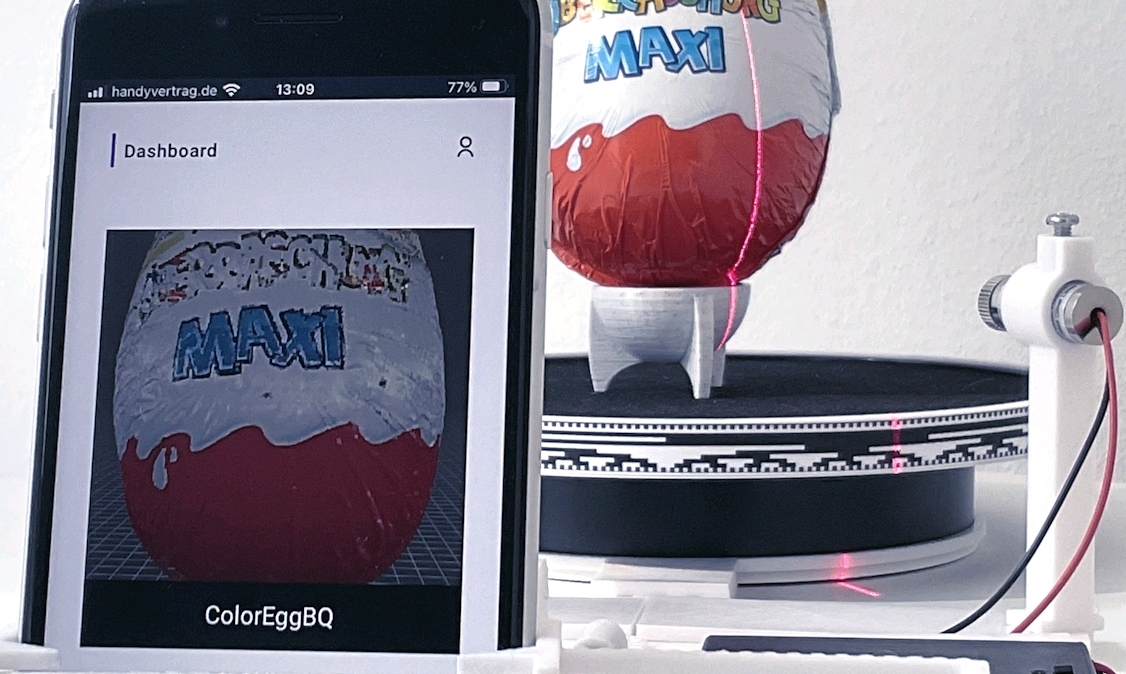

To date 3D scanning is prohibitively expensive to get everyone involved. So we created a 3D Printable, Affordable Laser 3D Color Scanner. Combining 3D printed parts, your phone, a turn table, a laser, and a Community Cloud Service.

Type: Commercial, Social Impact, Education

Website: https://ascand.xplicator.info/

What inspired you or what is the idea that got you started?

Traditional 3D laser scanners are too expensive to reach a broad creative audience in education and making. Due to the huge advances in this field, they also become outdated frequently ending up as landfill.

Traditional scanners are hardware and are stuck with whatever was placed into the box during production. They are limited in performance, as the quality of the cameras in these systems never stacks up against the smartphone you have in your pocket. And as standalone products, they can only leverage their limited build-in computing power.

Lastly, traditional production relies heavily on centralized and mostly China-based manufacturing specializing in low-volume hardware, making it very hard to estimate volume, timing, cost fluctuation, quality, and the impact on logistics

In the long term, we plan to use ASCANDs 3-axis scans for bringing spare personalized part production to everyone everywhere. With the minimal impact on our planet possible.

What is your project about and how does it work?

By leveraging the powerful camera in your smartphone, the power of Cloud computing, and advanced algorithms that benefit from the latest advancements in Computer Vision and Artificial Intelligence, we created the most widely available and powerful 3D scanning platform around, which we call ASCAND.

All ASCAND 3D 3D print files are freely available for download.

By allowing LOCAL 3D printers to take over GLOBAL manufacturing, ANY number of users can own an affordable and powerful 3D-Laser-Scanner. Anywhere. Anytime. No ships. No trucks. No waste.

We ASCAND with a special focus on commodity components for anything not 3D printable - primarily the turn table and the laser module.

The 3D scanner has four ingredients:

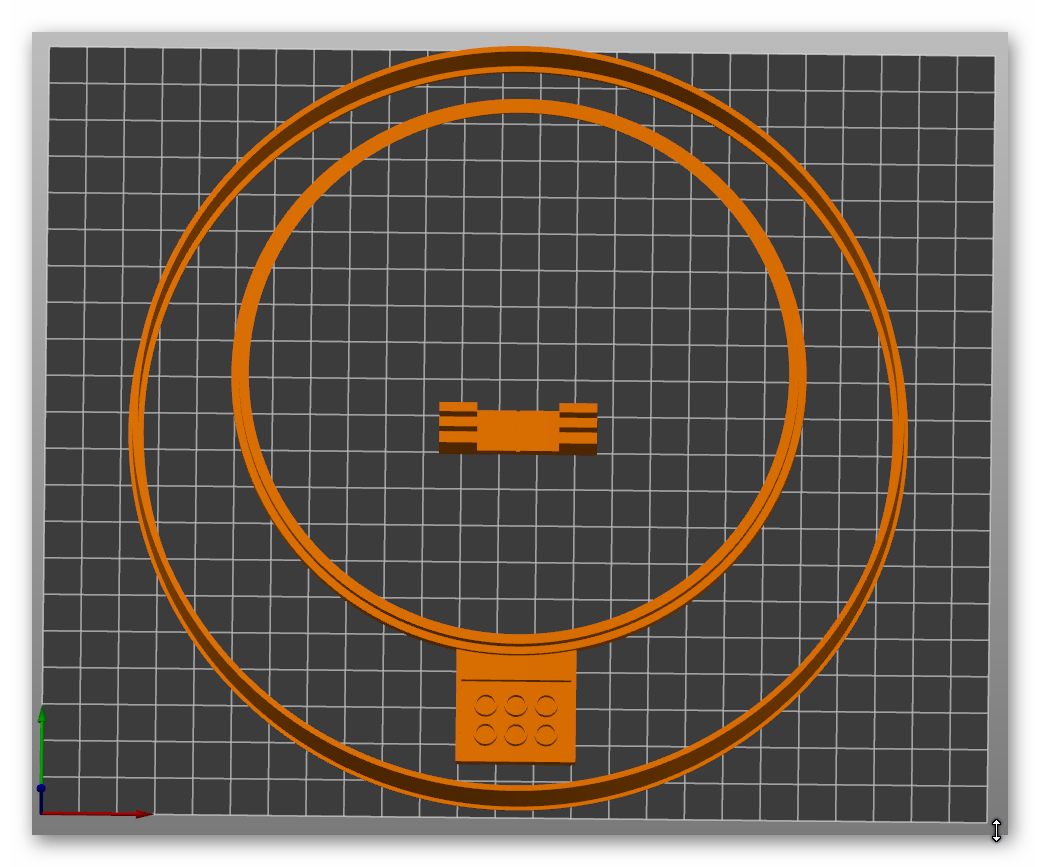

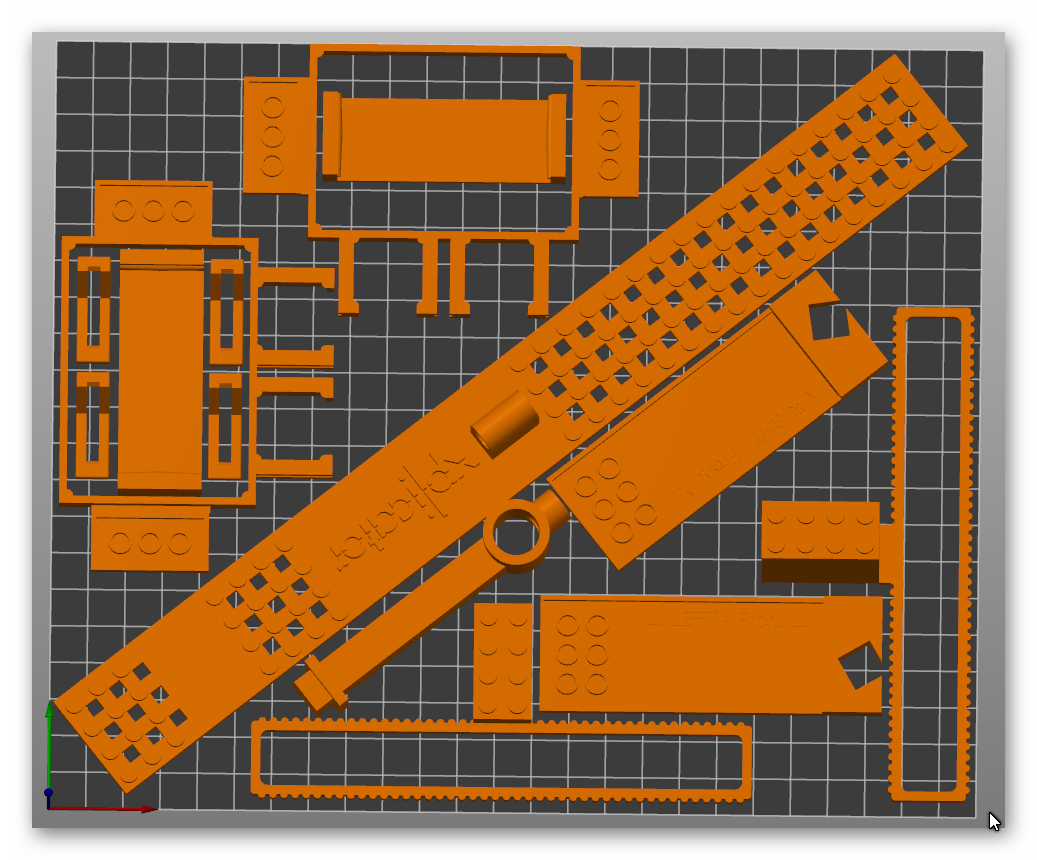

- The 3D printed parts for the 3D scanner structure

- A Turn Table, a Laser Module, a Battery Case, and 2 Lever Nuts

- A Block Code Tape that you place around the Turn Table Sleeve Ring

- Your Phone with your Internet Connection

What did you learn by doing this project?

Our design goal was to facilitate large scale distributed production of the ASCAND on a wide range of commodity grade 3D printers. In the easiest and most fail-safe way. With the widest range of eco-friendly PLA filaments. Clicking together as easy as LEGOs. No supports, no rafts, no post processing. This was a major challenge that we finally tackled after a lot of prints on a lot of different FDM 3D printers.

As everything is computed by a cloud service, we then had to write the laser triangulation software, deploy it into a scalable cloud environment, and create a web app that works on all iOS and Android phones without having to require an App installation. While we leveraged a lot of our prior experience applying the fast-moving AI, Computer Vision, and Mesh algorithms to hide the complexity from the end user took endless turns and versions.

What impact does your project have on others as well as yourself?

Initially want to enable everyone to participate in the 3D scanning space. Independent of budget or location.

Our longer-term vision is to be able to create spare parts for broken parts to get immediate replacements everywhere while reducing waste.

We already started working on this.